The King Milling Company has been family owned and operated since 1890. From our humble beginnings using the stone grinding process to today’s fully automated network of steel rolls, we have always pushed to be on the leading edge of milling technology to produce the highest quality flour and wheat products for our customers.

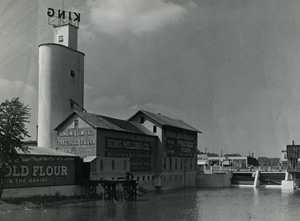

King Milling Company “Superior Mill” 1941

The first mill in Lowell, Michigan, the Forrest Mill, was built in 1844 on the east bank of the Flat River. In 1867, it was joined by the Superior Mill on the west bank. When the Superior’s owners filed for bankruptcy in 1890, the mill was purchased by a local lumber company owned by Francis King, his son Frank T. King, Reuben Quick and Charles McCarty. Thus, the King Milling Company was born.

The group quickly set to work updating the mill to the new “roller” system, which more than doubled its capacity to 500 cwt. (1 cwt. = 100 lbs.) of white flour a day. The company eventually purchased the Forrest Mill and converted it into a corn mill.

In 1900 another local lumberman, Thomas F. Doyle, purchased part-ownership of King Milling and his three sons, Charles, Renis and William, went to work for the company. In 1936, William Doyle assumed management of the company. Under his direction, significant operational improvements were made, and King Milling’s volume of business increased substantially. William directed the construction of new water turbines under both mills. He also supervised the construction of a new concrete dam across the Flat River to power the mills.

In 1943, the old Superior Mill burned to the ground. Instead of buckling under this setback, William used this as an opportunity to improve operations. On the site where the wooden mill once stood, William built a new state-of-the-art concrete mill equipped with all the most modern milling equipment of the time. When completed in 1945, the new mill produced 600 cwt. of flour per day and could store up to 80,000 bushels of wheat.

Tragically, William died ten days after the new mill commenced operations, and sons King and Mike assumed ownership. At the time, King, 23, was serving as an Ensign on a U.S. Navy destroyer in the Pacific theater of WWII; Mike was 15. The Navy granted King a 90-day emergency leave while his ship was being repaired following a Kamikaze attack, and he returned home to put his father’s accounts in order. By the end of the 90 days the war was over, and King was released from active duty. He became president of King Milling Company. Mike joined him as vice president after duty in the U.S. Army during the Korean Conflict.

King and Mike continued to look to the future as they increased the capacity of the mill to 5,400 cwt./day and added a mill capable of producing 4,000 cwt./day of whole wheat products. They also increased storage capacity to approximately 2.8 million bushels of wheat. During this time, King Milling was among the first to switch from the old bucket system for conveying flour to pneumatics. The company also introduced newer transportation systems including bulk trucking capabilities and a system capable of loading a truck with 50,000 lbs. of flour in just under four minutes.

King Milling developed a proprietary process in the 1960s that deactivates wheat’s enzymes for a longer shelf life. We made further refinements to the process in the 1980s and early 2000’s. This wheat is milled and sold under our Ceres® line of products.

Our progressive approach to milling continued with King’s son Brian, and Mike’s sons Jim and Stephen. With King’s and Mike’s help, the next generation of the Doyle family worked to fully automate operations, making King Milling among the first mills to do so.

In 1995, Brian became president, Jim senior vice president, and Stephen vice president. Since then, they have worked tirelessly to keep King Milling on the cutting edge of their industry, employing the newest machinery and milling techniques.

In 2004, the mill added a fifth floor and much of its equipment was removed and replaced. Improvements and additions brought capacity up to 8,000 cwt./day. While the same exterior structure built by William Doyle in 1945 remains, the mill is now 85 percent more space efficient and produces 13 times the amount it did when originally built.

B-Mill Construction, 2013

In 2013 a “B-mill” was built boasting all of the latest milling technology and is capable of producing 5,000 cwt./day of white flour.

In 2017, additional grain storage and grain drying capacity was built, taking the company from 2.8 million bushels of wheat storage up to 3.6 million bushels of storage capacity.

In 2019, King Milling built an automated packing system to pack its products into 25 and 50 pound bags as well as 2000 pound supersacks. This system is housed in a 30,000 square foot warehouse constructed with the most sanitary design.

In August 2022, King Milling began the construction of another new flour mill and addition flour storage and loadout facility. The new “D-Mill” started up full production in December of 2023.

The D-Mill was built using the latest in technology and sustainable practices, and boasts a production capacity of 8,000 cwt of white flour per day. This increased King Milling’s total white flour capacity to its present level of 21,000 cwt per day between all three mills, and 25,000 cwt per day of total capacity including the whole wheat mill. With the D-mill, an additional 140,000 bu of wheat storage capacity were added, bringing the Company’s total storage capacity to 3.74 million bushels.

Notably, the City of Lowell’s centennial book of 1931 cites the King Milling Company’s daily capacity at 495 cwt., with an annual grind of 250,000 bushels. Our mills now produce the 1931 daily capacity in approximately 30 minutes and grinds 250,000 bushels of wheat in about 5 days. It’s also interesting to note that in 1890, Michigan had 700 flour mills. That number dropped to 534 by 1900 and 28 in 1958. Today, only six flour mills remain in Michigan.

While times may change, the Doyle family remains a constant at King Milling, as the fourth and fifth generations, including brothers Patrick and Regan and cousin Mike, work side-by-side with their fathers and other family members.

We are fortunate to work with a great team of dedicated employees, many of whom are long term including several who are multi-generation employees themselves. Some of these employees have worked at King Milling longer than we have. Without the hard work and dedication of these fine individuals, none of the milestones and success mentioned in this history would have been possible.

In 2022 Brian became Chairman, Jim became President and Steve, Senior Vice President. In the fifth generation, Patrick became Executive Vice President and Regan, Vice President of Operations.

At the King Milling Company, we take pride in our history but always look to the future. We strive to stay ahead of the technological curve to produce the consistent, high quality flour and wheat products our customers expect.